Slit-In Type Gasketting Manual 6. Installation use and or maintenance of SONDEX plate type heat exchanger as well as not complying with the instructions in this manual.

Chapter 4 Sep Phase Iii Detailed Design Phase Managing Software Deliverables A Software Development Management Methodology

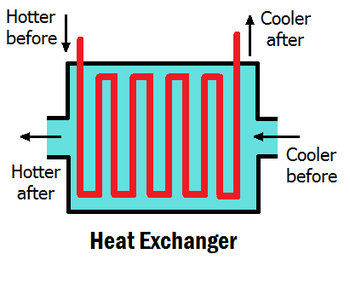

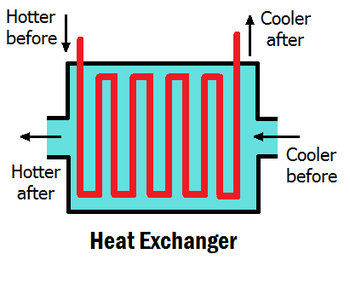

Heat Exchangers Visually check heat exchanger for leaks at the connection points to the heat exchanger as well as the body of the heat exchanger.

. These fluids never encounter each other due to being separated by the heat exchanger. Then check your pressure gauges at each end of the PHE to make sure the pressure. Tube inspection can be done using eddy currents down the bore of the tube to determine any wall thinning or fretting.

The good news is its rarely too late to maintain your heat exchanger plates. Inservice inspection should cover items such as tube to tubesheet weldsjoints including ndt if they are welded. Great info One thing I was looking for but did not find is the preferred way to pipe a tube shell heat exchanger I have a problem with 2 buildings connected with a central boiler plant.

The main functionality of a Plate Heat Exchanger is to transfer heat between two fluids at different temperatures which improves efficiency. Heat exchangers are used to optimize heat transfer from one gas or liquid to another during processing and cleaning in place CIP. Manuals for the HISAKA Plate Heat Exchanger consist of the following seven related documents.

Valving off unit draining of fluids disconnection of pipes verification of plate pack arrangement and primary leakcontamination tests such as Thermalines patented CCT system. Maintaining a plate heat exchanger and its related cost is not just a good idea - it is a necessity for any successful business strategy concerned with its continued manufacturing productivity. Operation and Maintenance Manual 3.

The medias can. Plate heat exchanger maintenance checklist Manufacturers Factory Suppliers From China We welcome you to definitely inquire us by simply call or mail and hope to develop a prosperous and cooperative connection. Please note that our plate type heat exchangers are specially designed and built for the operating conditions pressures temperatures capacities and type of fluids provided by the customer.

However there are ways to minimize the effects of a plant. It is safe to say that it would be rare to find someone in this industry that does not believe in having a plate heat exchanger maintenance strategy. This is lost production time which translates to reduced output and efficiency.

The organic versus synthetic decision is driven by the heat exchangers design features including factors relating to life length such as thermal stability heat transfer efficiency and purity 2 and cost see Figure 1. Semi-Welded Plate Heat Exchanger SWPHE. Regular PHE service procedures generally include.

The key is knowing what to look for when it comes to early signs of aging mitigating processing conditions that might contribute to excess wear and most importantly creating a regular maintenance schedule. When its time to clean your shell and tube heat exchanger theres a good chance that youll need to shut down operations temporarily. Plate Cleaning Manual 5.

Clean the heat transfer area. SangoBay Industrial 21 Oct 03 0412. Plan your maintenance budget.

Therefore the cleaning and maintenance of the heat. Mechanical Confirm plate and frame units are tightened as recommended by the manufacturer. We have a made a Plate and Frame Heat Exchanger Maintenance Checklist.

Sweep up area and remove any debris. Gasketting Manual Total 10 Models 4. Perform this kind of maintenance at least once every six months.

Create a Plan for your Heat Exchanger Routine Maintenance. Mixed Gasket Materials Manual and 7. Because it specifically deals with and contains information about utility power generating heat exchanger applications.

Either be in liquid or gaseous form. The main applications in refrigeration systems are evaporators and condensers. Eliminate and clean debris and buildup check asset user guide or warranty manual for recommended chemicals Inspect relief valves.

VHX has tips of Good Maintenance for Plate Heat Exchangers you re welcome to send your inquiries to us for detailed offers at the best price and fast responding time. Fouling or aging can result in degraded heat exchanger performance and additional operating and energy costs to compensate for the difference in target temperature. Typically a plate heat exchanger will consist of several parallel plates positioned above each other thus creating a passage in which the fluid can flow between.

Figure 1 highlights the first important point regarding maintenance to use a fluid with the lowest impurity levels. Dimensional checks should be staight forward. Clean up any spilled chemicals.

Both are water source heat-pump loops both heat exchangers are approx 6 years old. 1 heat exchanger is piped with the boiler water flowing thru the shell and it has more than enough capacity. The plate heat exchanger has a small flow channel.

Shanghai Exheat Industries Co Ltd 86-18069958252. A plate heat exchanger is used to transfer heat energy from one fluid to another. As mentioned above regular visual examinations are important make sure the plate pack is tightened to specification the carrying and guide bars are lubricated and the gaskets appear undamaged.

The Semi-Welded Plate Heat Exchanger transfers heat energy between two medias without intermixing. Common BOP heat exchangers BOP heat exchangers are of various types and configurations from basic shell and tube exchangers to plate and frame exchangers finned coils double-pipe exchangers and many others. Insulation may be hiding small leaks so also check for areas of wet or water stained insulation.

Advantages of plate heat exchangers High heat transfer coefficient. Read the full article here. Regular maintenance will help ensure that your plate heat exchanger stays sanitary and operational.

Record your results and data from the maintenance test.

Checklist Heat Exchangers Pdf Pdf Nondestructive Testing Welding

Plate Heat Exchanger Service Checklist Rasmussen Mechanical

Plate Heat Exchanger For Dummies Rasmussen Mechanical

Practices For Maintaining The Availability Of Plant Heat Exchangers

St Exchanger Inspection Checklist Pdf Industrial Processes Building Engineering

0 comments

Post a Comment